PRODUCTS

- Home

- Products

- DEWATERING EQUIPMENT

- CLOTH TRAVELING FILTER PRESS

DEWATERING EQUIPMENT

CLOTH TRAVELING FILTER PRESS

DEWATERING EQUIPMENT- Features

- Special Recognition by Japanese Ministry of International Trade and Industry.

- Two Excellent Pollution Prevention Machine.

- Prize of Industrial Science and Technology by the Director General Agency.

- Excellent Energy-Saving Device.

- The President's Prize of Japanese Machinery Federation.

Description

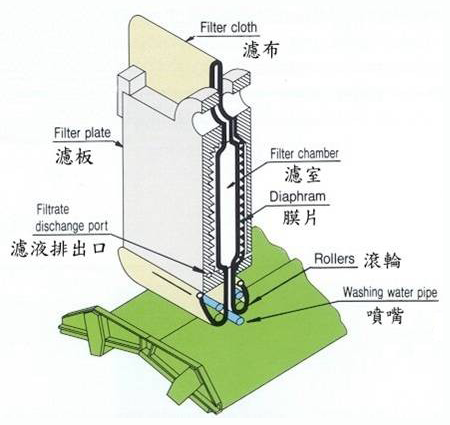

The Ishigaki LASTA Press is an advanced filter press featuring a variety of unique features, including a top-feed slurry supply, separately driven cloth traveling and simultaneous opening and closing of all plates.PRINCIPLE AND STRUCTURE

| 1. Plate Closing | Feeding | Compression |

|---|---|---|

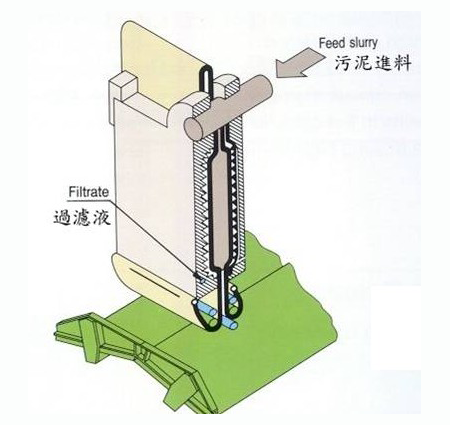

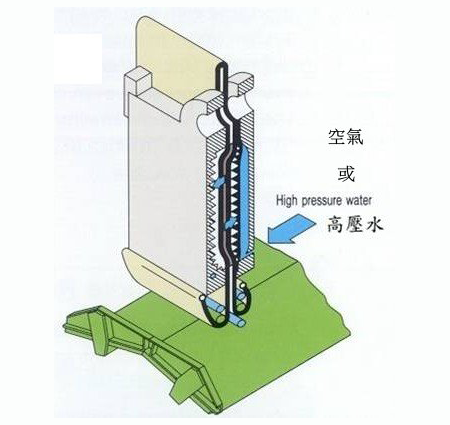

| When the start-up switch is activated, the hydraulic pump operates, and the hydraulic cylinder clamps the filter plates, thus forming a filter chamber. | The slurry is fed via the feed port at the top of the filter plate. The solids in the feed build up as dry cake while the filtrate exits through the filtrate ports. | Upon completion of the feeding process, pressurized water or air is injected into the diaphragm. The filter cake is further compressed and dewatered. |

|

|

|

| video | video | video |

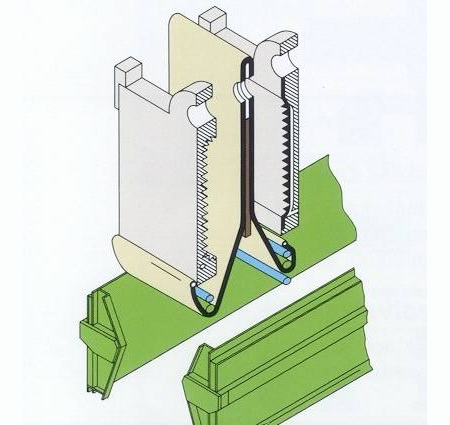

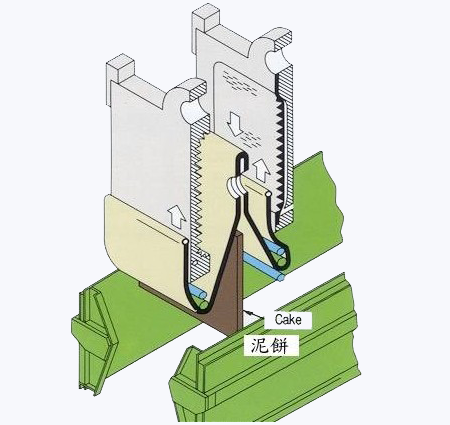

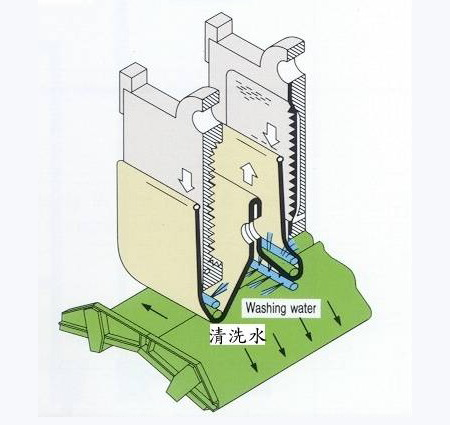

| 4. Plate Opening | 5. Cake Discharge | 6. Cloth Wash |

| After the compression process ends, the hydraulic pump automatically operates, driving the hydraulic cylinder and opening the filter plates. | When the filter plates are fully opened all the filter cloths automatically travel down, around the lower plate roller and discharge the filter cake. | After the cake discharge is complete, the filter cloth returns to its original position. A cloth wash can then take place with the automatic cloth travel system. |

|

|

|

| video | video | video |

ADVANTAGES

| 1. Fully Automatic Operation | 2. Superior High Dryness Dewatering Performance |

3. Complete Cake Release | 4. Rapid Cloth Washing |

|---|---|---|---|

| 24hours a day Fully Automatic Operation is available. | Equipped with a top-feed slurry feeding design and a unique high compression diaphragm mechanism. | Traveling Cloth Mechanism can easily release cake from the cloths as the cloth passes through the guide rolls. | The filter cloth for each chamber is washed simultaneously leaving no residue. The total washing time is only about one minute. |

| 5. Increased Processing Capacity | 6. Longer life time | 7. Simple Cloth Changing | 8. Safety design |

| The filter cloth traveling mechanism substantially reduce the time required for cake release and cloth washing and, therefore, greatly improve processing capacity. | Most of LASTA filter press can have an operating life time longer than 20 years | The filter cloth can be replaced for each individual chamber. The filter cloth travels with chains on both sides, so correct positioning is fast and simple. | Installed with protecting devices at all stages of operation. LASTA Press is very safety for long time automatic running. |

APPLICATION

| APPLICATION | |

|---|---|

| 1. Agricultural Products 2. Fermentation 3. Gypsum 4. Kaolin 5. Metallic compounds *Oxide *Hydroxides *Carbonates *Sulphates 6. Chemical Processes |

7. Oil Extraction 8. Talc 9. Pigments and Dyes 10. Resins 11. Sludges * Municipal * Industrial * Alum * Blast Furnace |