PRODUCTS

- Home

- Products

- CERAMIC MEMBRANE

- CERAMIC MEMBRANE

CERAMIC MEMBRANE

CERAMIC MEMBRANE

CERAMIC MEMBRANE- Features

- High flux rate reduces footprint, energy & chemical consumption.

- Chemically inert provides high chemical resistance & no permeability decline.

- Negatively charged surface reduces fouling of organics and oil.

- Extremely hard & durable makes it easy to clean.

- High solids loading capability from few ppm to several % of TSS loading.

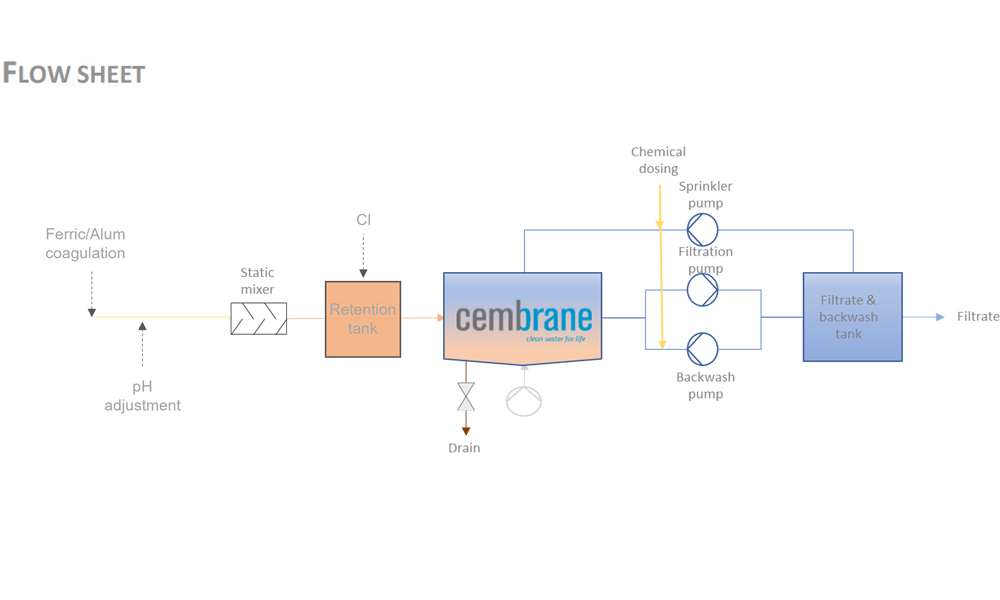

- Simplified flow sheet combine filtration with sedimentation, flotation & absorption into one process step.

Description

Cembrane is a ceramic SiC membrane module made of silicon carbide particles after high temperature sintering, and produced by the original Danish factory, its filtration accuracy is 0.1 μm.PRINCIPLE

| PRINCIPLE | |

|---|---|

| Immerse the module in water, the SiC flat ceramic membrane adopts cross-flow filtration technique to produce filtered water, then the water is collected to the main pipe and discharged to the next processing stage . The suspended solids, bacteria are trapped within the membrane surface develop into the filter cake layer. | |

.png) |

.png) |

| Design the flux and filtration area according to the water quality and local conditions, then plan the most suitable treatment module. | |

.png) |

|

| Through the module negative pressure suction operation, combined with filtration, precipitation, floating removal, absorption and other steps to form a one-stop treatment, improve the filtration efficiency of the inflow water, and optimize the quality of the treated water. | |

|

|

ADVANTAGES

| ADVANTAGES | |

|---|---|

| 1. High Filtration Accuracy 2. High Permeability The transmembrane pressure difference is low and filtration flux is high due to the membrane with excellent hydrophilic surface. 3. Long Service Life The SiC material is good durability and requires less frequent replacement after a long-term operation. 4. Stable Performance Applying aeration and an accurate backwashing time setting to control the membrane fouling for avoiding the shutdown damage. 5. Low Operation Costs The ceramic membrane is simple and easy to maintain, can effectively reduce chemical clean, and have low energy consumption, long service lifetime, and high filtered water production rate. 6. The Comparison of Membrane Bioreactors |

|

(1).png) |

|

(1).png) |

|

APPLICATION

| APPLICATION |

|---|

| Typical Applications: 1. Groundwater:Iron and manganese removal in drinking water. 2. Surface Runoff Water:Water Plant and Small Water Treatment Facilities 3. Reclaimed Water:Industrial Wastewater/ Domestic Water Recycling/TSE. 4. Whet Wastewater:CMP/ BG Wastewater. 5. Membrane Bioreactors System (MBR). 6. Non-soluble Powers Filtration. |